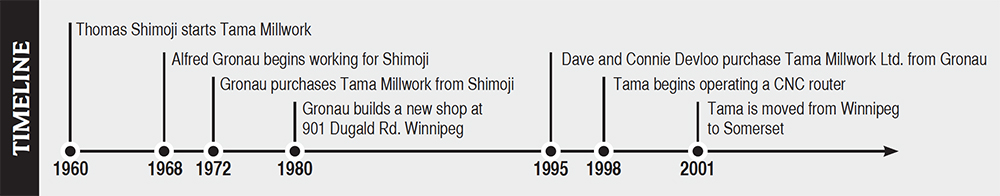

In the 1960’s, a second-generation Japanese-Canadian man named Thomas Shimoji started a woodworking company called Tama Millwork. “Tama” has many meanings in Japanese, some of which are “treasure”, “pearl” or “sphere”. The translation that was passed down was “fast as a speeding bullet”.

Primarily, the company manufactured millwork and store fixtures for retail stores across Canada, all of

which were machined and fabricated from the shop at 847 Marion Street in Winnipeg, Manitoba.

Alfred and Erika Gronau, immigrants from Germany, immersed themselves in the woodworking life when Alfred began working for Mr. Shimoji in 1968. In Germany, Alfred had trained towards, and achieved, the title of Meisterbrief, meaning “Master Cabinet Maker”.

Alfred worked for Shimoji from 1968-1972, when he purchased Tama and incorporated it, giving new life to Tama Millwork

Ltd. In 1980, Alfred built a new shop at 901 Dugald Road, from which he ran the business until 1995, when Connie and Dave Devloo purchased it.

In the years following, many changes took place, as Dave felt that technology was the key to the future. Tama became the first company in Manitoba to implement “Nested Base Manufacturing” with the use of a CNC (Computer Numerical Control) Router.

The business continued to grow in Winnipeg until 2001, when it was moved to Somerset, Manitoba, the small town where Dave grew up.

“From 1991-1995, I was doing cabinetry from my home shop in Winnipeg.” Dave says. “Our business has seen a lot of changes since then.

“Meeting Alfred, and later purchasing Tama from him, were pivotal moments in our lives.”

Today, the business is multifaceted, manufacturing a variety of millwork for every room, residential and commercial.

The business utilizes a mixture of software to “draw” a project for the customers and create 3-D renderings. This makes it easier for customers to picture exactly what they are getting.

Once the job is confirmed, it is programmed for machines to cut everything out, creating a “Screen to Machine” operation.

Using technology, Tama has taken old-world furniture making traditions and applied them to cabinetry. Using mortise and tenon joinery, Dave and Connie pride themselves on having the strongest model for construction in the industry.

“When you buy a quality-made cabinet, it should last as long as it takes to replace the tree it’s made from,” Dave says.

Another aspect of the business is wholesale, where other cabinet shops can get custom cabinet parts manufactured for them. The advantages of custom cutting are numerous; not only is a good yield passed on, but a large portion of manual labor is removed from a shop’s overhead. Shops that outsource to Tama notice not just savings but a service that ensures their job is done quickly and punctually.

Custom finishing is yet another branch of the Tama tree. Being one of the only shops in Manitoba exclusively using waterbased stains, dyes and lacquer, instead of harsh solvent-based treatments, Tama reduces the impact that finishing has on the environment.

Tama Millwork is continuously evolving and growing bigger.

Dave and Connie intend to expand their business as well as their shop in the next few years.

“By expanding, we can increase the impact that we have in this community, bringing in business, workers and interest.”

Being an employer in a small area has an impact on many local businesses. Dave stresses, “With our growth, we encourage the growth of the community. We want to be able to give back to the community.”